Rational Design

Craftsmanship

Stable accuracy

High consistency

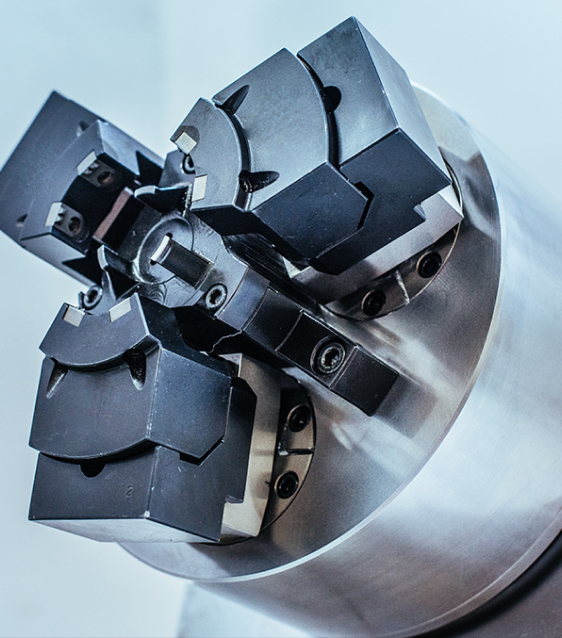

Universal ball lock chuck (self centering/floating)

characteristic

- Compatible with both inner and outer diameter clamping

- Excellent rear pull mechanism ensures very stable clamping

- Claw with radial swing function, perfect for gripping workpieces with poor roundness

- Re cutting with minimum clamping amount for workpieces with draft angles

- The clamping of circular motion ensures longer chuck life

- Internal parts can be replaced

- Using special waterproof sealing rings, with excellent waterproof and dustproof capabilities

- Most suitable for rough machining use

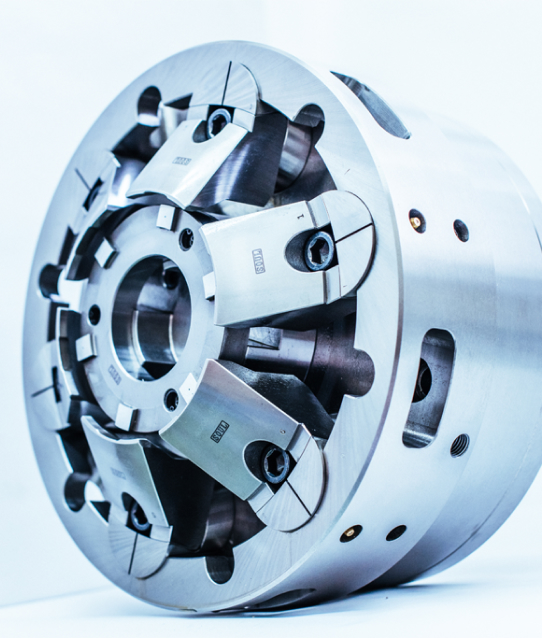

Pin spindle chuck (inner diameter PA/outer diameter OPA)

characteristic

- The powerful back pull function ensures that the workpiece firmly fits the positioning block without causing any warping

- Large feeding gap, most suitable for automation

- High rigidity makes the clamping of the inner and outer diameters very stable, with excellent resistance to cutting forces

- Can perform airtight testing on the gripper to better prevent errors during automated processing

(The clamping position of the gripper needs to be within a tolerance of ± 0.03mm in the front sequence for air tightness)

- High speed and good sealing, iron filings cannot enter the inside of the chuck body

- Most suitable for precision machining use

OPA – Jaw rotating chuck

characteristic

- Cross clamping based on high-precision OPA development

- The claw can rotate and has a large opening

- The rotation direction of the claw can be designed according to actual requirements

- Not limited to front loading, it can also be designed as a chuck side loading

- According to actual needs, the rotation direction of the gripper can be designed, with a difference in rotation time, which can achieve high-precision cross clamping that cannot be achieved by a long stroke 3-jaw chuck

Mandrel collet

characteristic

- High torque transmission

- Double cone back pull mechanism

- Spring collet in contact with the octagonal plane of the core shaft

- High precision and stability

- There is a limiter to prevent excessive expansion of the collet

- Can be designed as double tube clamp, eccentric tube clamp, spline tube clamp, composite tube clamp

- Standard products in stock

- Suitable for precision machining inner diameter clamping

Film chuck

characteristic

- Fully sealed construction ensures high service life

- Built in cylinder design, commonly used for spiral machining of scroll parts in air compressors for machining centers

- High repetition accuracy TIR0.002mm

- Easy replacement of claws, positioning blocks, etc

- Suitable for precision machining of lathes, grinders, and machining centers

Pitch chuck

characteristic

- Gear pitch circle chuck developed on the basis of thin film

- The design of the cage can correspond to different sizes of gears, and the cage can be replaced

- Fully sealed construction ensures high service life

- Capable of 3 point clamping, 6 point clamping, pitch circle centering+surface pressing

- Suitable for lathe machining with gear inner diameter

ASA – High speed rotating cylinder system

characteristic

- Maximum speed 12000 rpm

- According to actual needs, 3 or 4 layers of pull rods can be provided

- Customizable length according to spindle requirements

- Can correspond to high-pressure cooling

- Capable of simultaneously achieving central water outlet, central air blowing, and airtight detection functions

AC ultra precision translational chuck

characteristic

- Chuck size 2.5-10 inches

- Claw form: 2 claws, 3 claws, 4 claws

- Repetitive accuracy 0.0015mm

- Fixed gas ring can be added (corresponding to Polaris)

DC ultra precision thin film chuck

characteristic

- Repetitive accuracy within 0.0004mm

- maintenance-free

- Ultra high speed (up to 12000 rpm)

- High lifespan

- Both inner and outer diameter clamping can correspond

- Suitable for use in grinding machines, measurement and precision turning

- Chuck size 3-6 inches (suitable for precision small parts processing)